Digital Solutions

We accelerate transformation and digitization by partnering with best in class. Therefore, we constantly seek efficient and cost-reducing digital solutions for the maritime industry to simplify and speed up processes across all aspects of ship management.

Please find an overview about projects we deal with, work on, and partly have already implemented – always having in mind an added value for our customers in means of costs, transparency, efficiency, and safety!

Cooperations

IHM Maintenance with NautilusLog and SGS

Zeaborn Ship Management digitizes the IHM Maintenance process to ensure continuous conformity of the inventory. A smart solution from NautilusLog connects and integrates all key stakeholders, manages supplier communications, integrates and takes care of the crew, and most importantly can identify and solve IHM issues before they arise.

Visit: https://www.nautiluslog.com

Optimization of lubricant procurement with Closelink

We strive for an easy and frictionless procurement process tailored to our needs and requirements. With a few clicks we manage our inquiries, orders and related communication with Closelink’s tool. The tool helps to find the best lub oil suppliers for all global ports, and at the same time also makes sure to get the best out of your existing lub oil contracts.

Visit: https://www.closelink.net/

SHIP PERFORMANCE & RENEWABLE ENERGY DATA COLLECTION AND ANALYSIS

Zeaborn Ship Management and Eco Marine Power are collaborating on an innovative project to digitize, collect and analyse ship performance data (including fuel consumption) using a computer automation system, and also studying the use of solar power and other energy saving devices onboard our managed vessels.

Product Development

We have already launched trials or are working with partners on a concrete product in these fields:

Measure sustainability: Environmental, Social, Governance (ESG)

We are fully aware of the enormous scope and impact of ESG issues on the economy. We can make a holistic portfolio assessment of your vessels in terms of “green requirements” (energy efficiency and future compliance) and we can execute the necessary conversion/ retrofit measures based on the results.

Save money and increase safety with remote inspections onboard!

We evaluate various digital solutions in this field: While easing the burden on the crew with digital, user-friendly tools to enable remote inspections we aim to save money and increase safety by identifying incidents before they occur. Especially in Corona times a focus project.

Zeaborn Ship Management works on Digital Reporting to collect data on board once and then distribute it to the respective systems –effective and time-saving.

We aim at taking 360°- pictures on our vessels to visually assess the complete condition of the vessel and then enable remote viewing, documentation, reporting and familiarizing with the crew, preparing projects or compare sister ships.

In this context we also deal with “3Net”, with their assistance tools for remote surveys. This technology enables us to take live-pictures with a helmet-camera and instruct the crew precisely from shore.

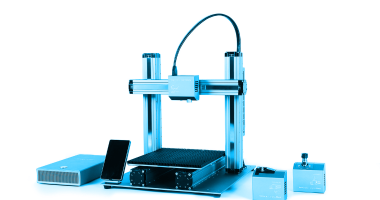

Reduce downtime with Additive Manufacturing (3D-Printing)

In a joint industry project, we are constantly looking at opportunities where the 3D-printing technology can be implemented to replace conventional materials used in spares, structural parts, etc. Printing parts locally can achieve a better resistance to corrosion, lower transportation costs, and simplify logistics.

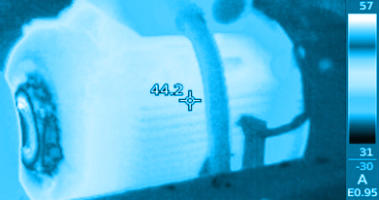

Thermal imaging – enhanced condition-monitoring & maintenance

Deployment and use of thermal imaging devices on board vessels – the digital heat-sensing cameras identify hot-spots and give early warning of developing problems. Such non-invasive checks provide better condition monitoring of running machinery, electrical switchboards/ connections, instrumentation, and other areas onboard, allowing for targeted and condition-based maintenance.

This has been approved by many owners as they see the benefits of such preventive maintenance, in reducing the risk of breakdowns and increased productivity from reduced off-hire/ downtime.